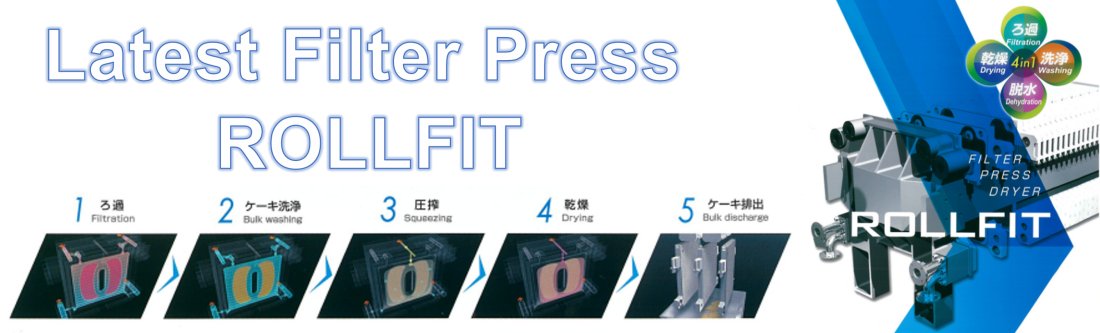

Filter Press and Filtration Process

Filter Press

Filter Press has features of higher level dehydration than other industrial dehydrators. Filter Press is mainly consisted of Filter Plate, Filter Cloth, Frame, Cylinder, and in automatic type Filter Press, Scraper, Dripping Pan, Plate Shifting are equipped. Slurry is pumped into Filter Plate and filtrated by filter cloth. Filtrate is discharged at the bottom of plates, and solid remains as "Cake" in each chamber. Cake formed in each chamber is discharged by its own weight or scraper in automatic type.

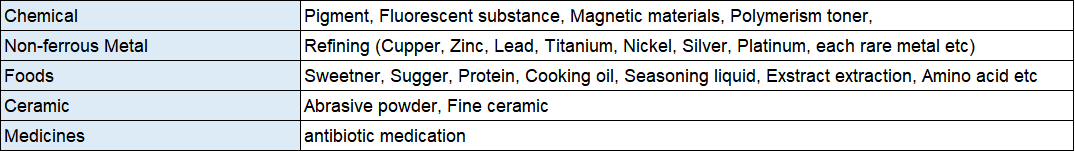

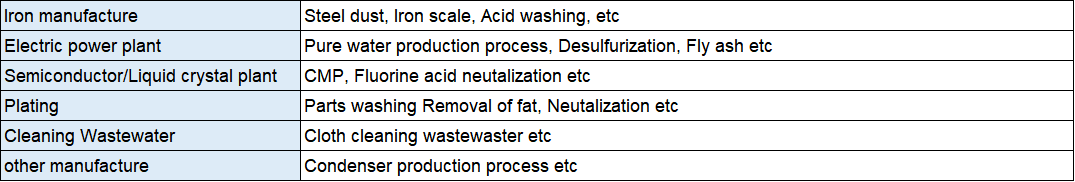

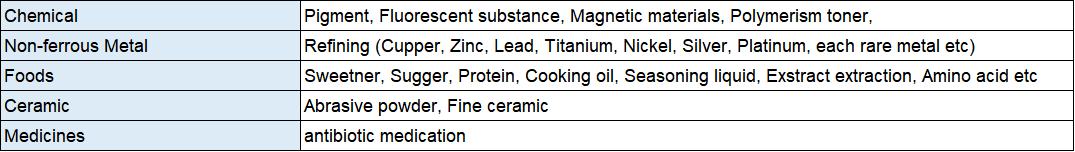

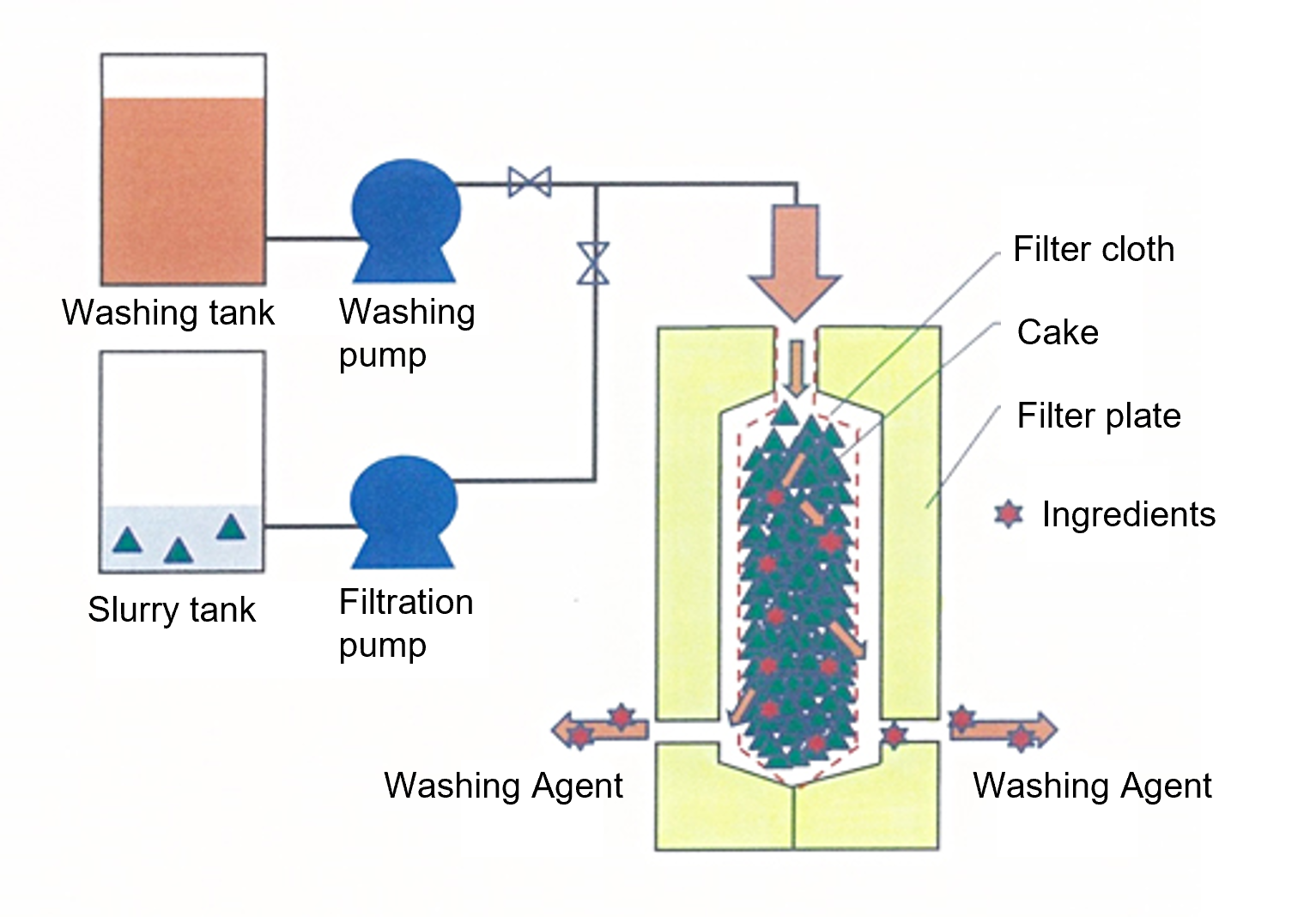

Filter Press is used for Wastewater treatment and products manufacturing. Table below is major applications of Filter Press.

Product Manufacturing

Wastewater Treatment

Kanadevia Filter Press has features of High level of dehydration, excellent cake washability and stable cake discharge. Our variety of cleaning methods and cake washing know-how supply and discharge washing agents smoothly result in high washing efficiency and saving water consumption.

Filtration Process

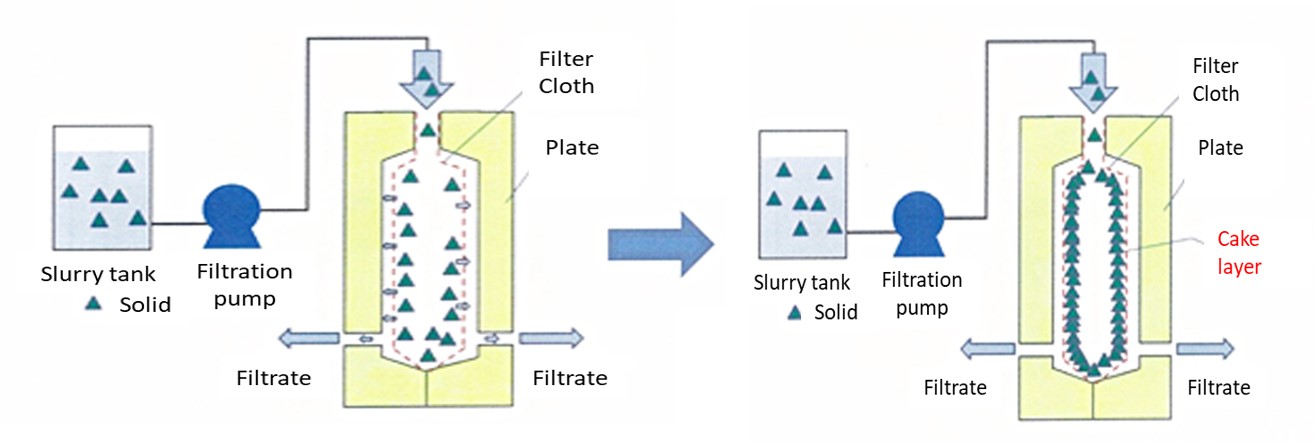

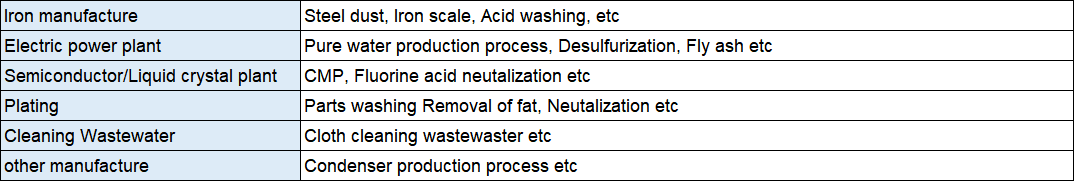

Filtration

Slurry is supplied to chamber for filtration under 0.2 – 0.7MPa pressure (standard: 0.4MPa).

Cake layer is gradually created in the chamber. This layer can filtrate sub-micron particles which is smaller than filter cloth gap.

Outcome filtrate volume becomes less as the pressure in the chamber increases due to resistance of cake layer accumulated in the chamber.

Filtration ends when it comes to set time, pressure or discharge volume of filtrate.

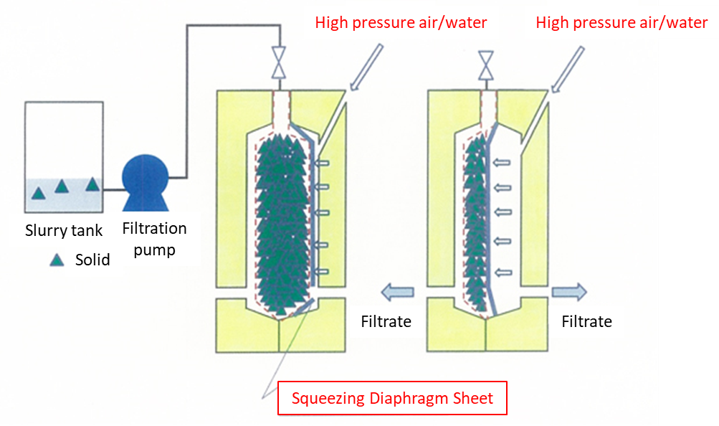

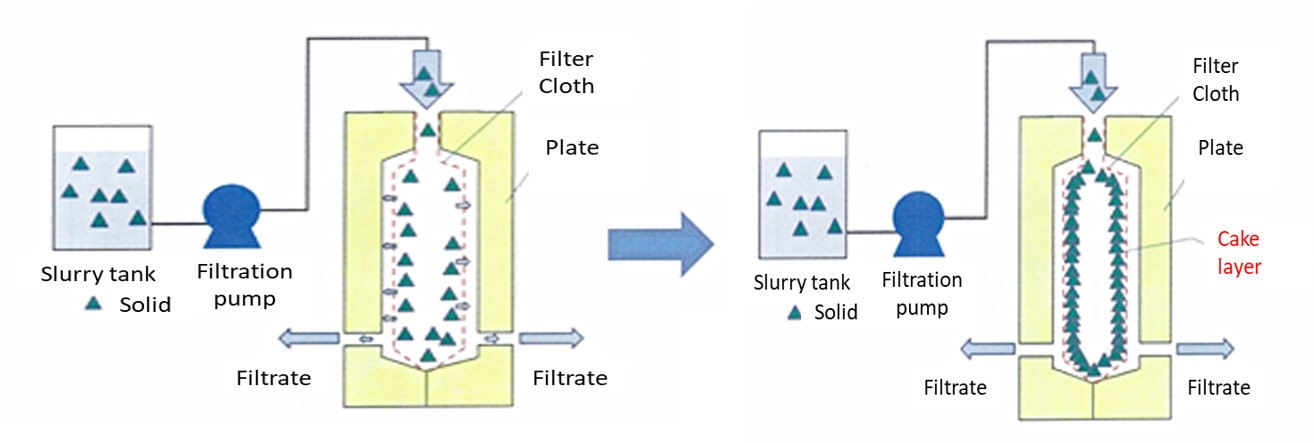

Squeezing

Cake layer is compressed and squeezed by Diaphragm Sheet expanded with air (0.7MPa) or water (1.5 / 2.0MPa). After squeezing, cake layer is dehydrated and moisture is lesser. Also, remaining filtrate can be separated and collected.

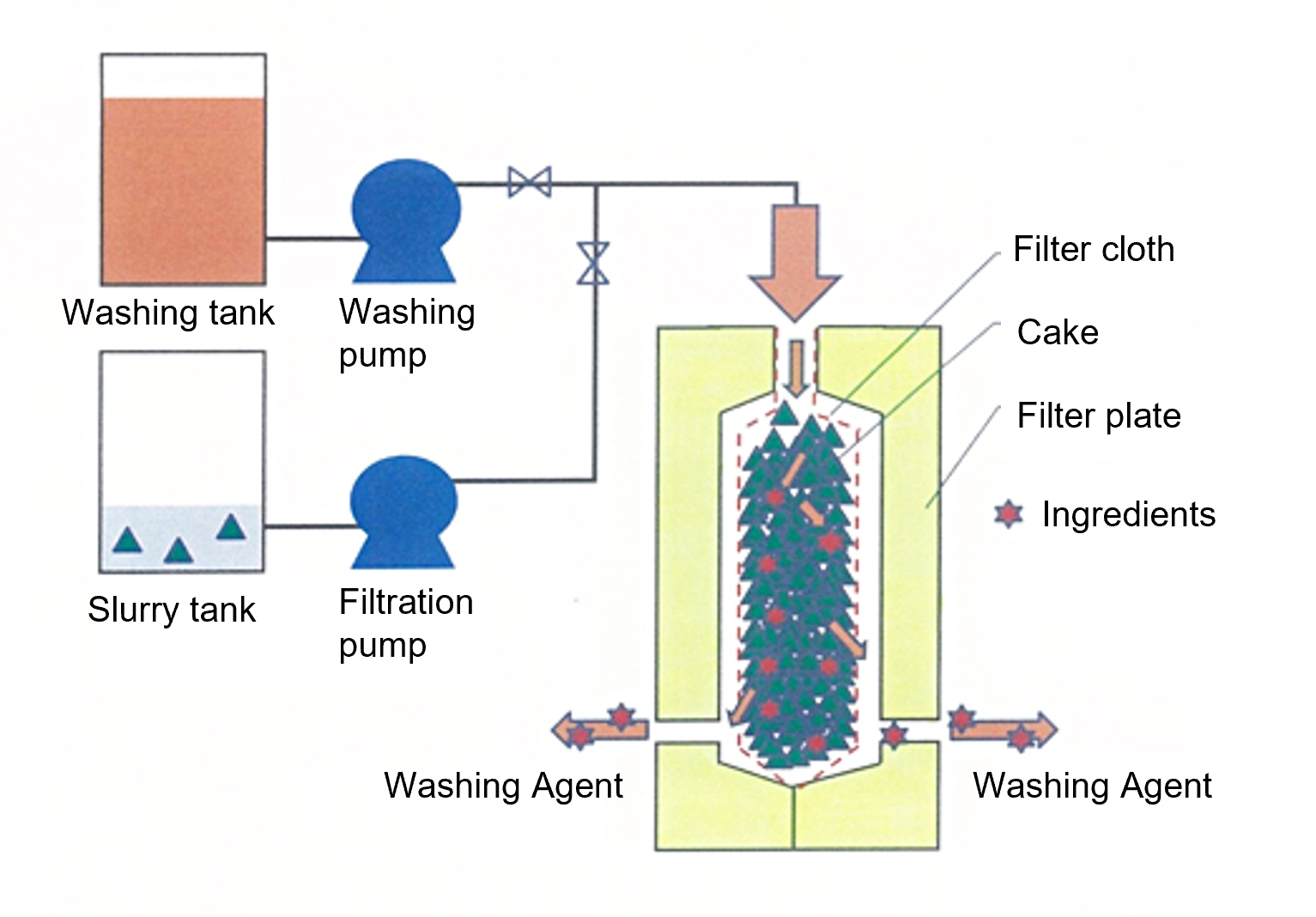

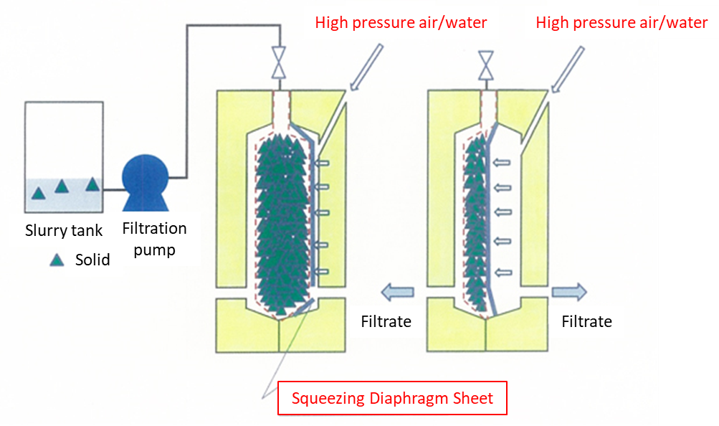

Cake Washing

Washing agent is supplied to chamber to wash cake layer, causing Extract of ingredients and purify cakes

There are two method to wash cake.

1. Washing agent is supplied from slurry feeding inlets (Feed Washing Method).

2. Washing agent is supplied from outlet of filtrate and flow through cake layer to discharge

at other bottom corner (Back Washing Method).